Finished product first :)

Graphic photo shot by yours truly, and then made in Photoshop!

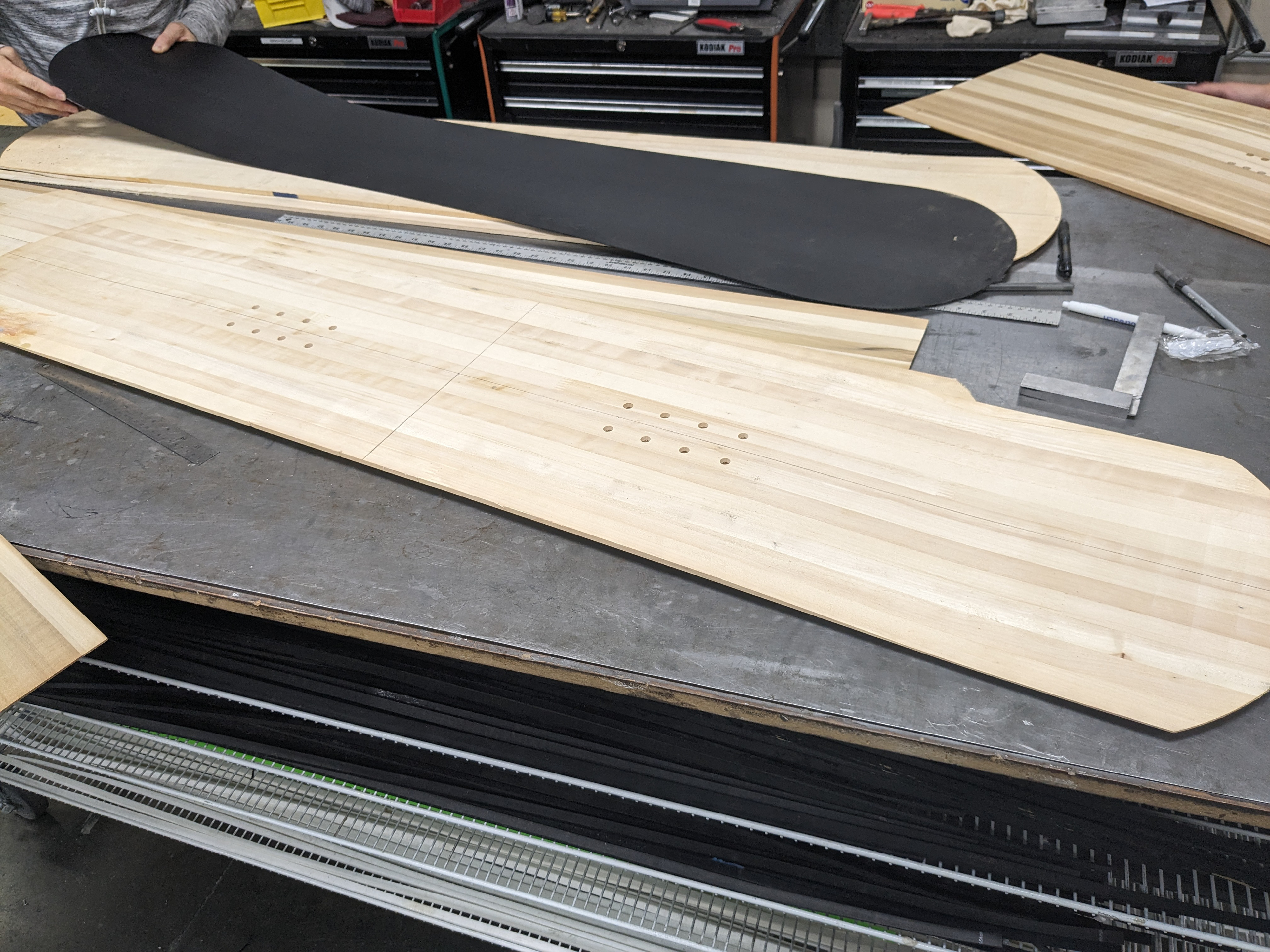

Core blank.

Covering the holes for the threaded inserts.

Milling out the shape.

Core shape complete!

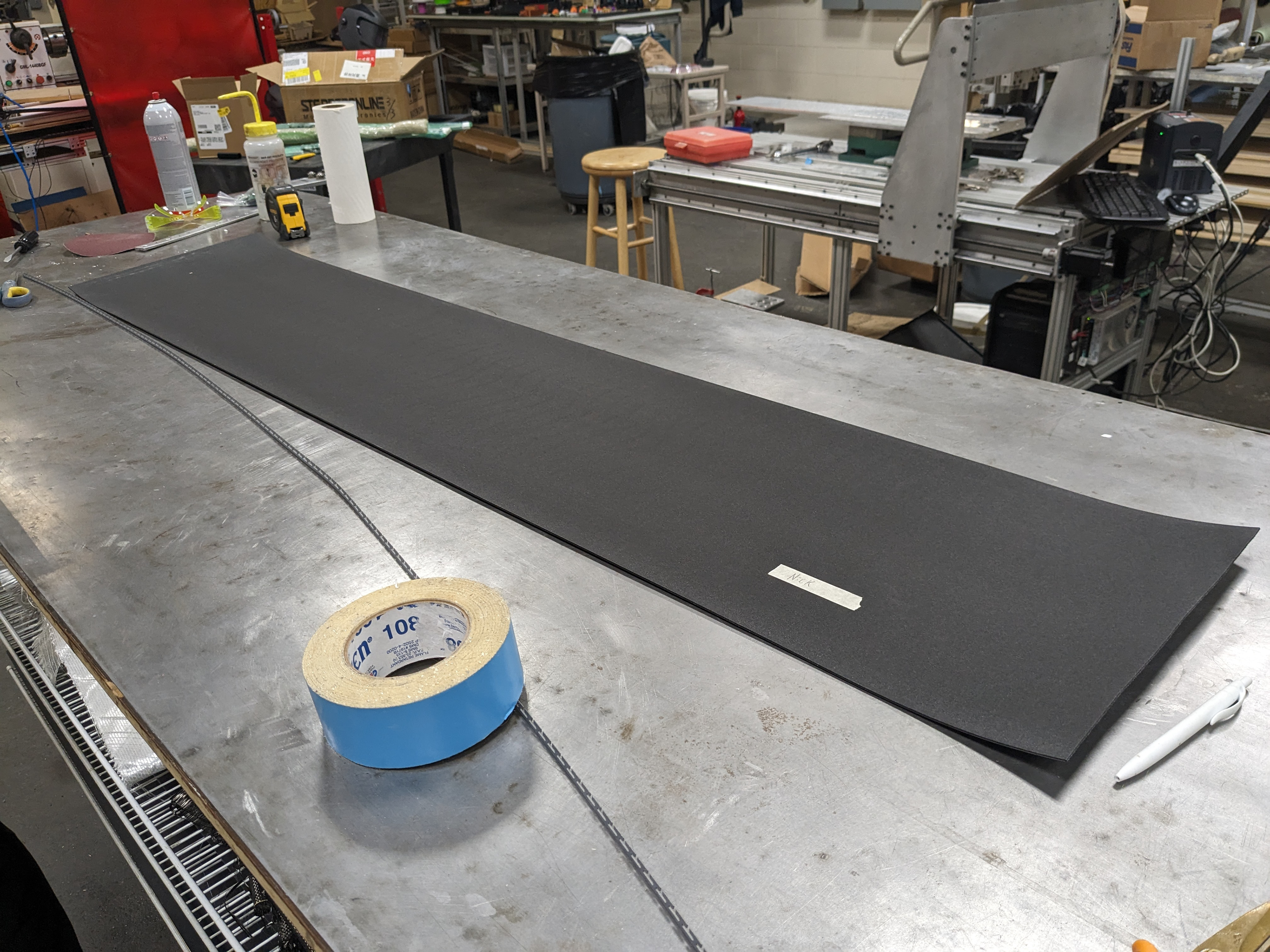

Raw base material.

Prepping core for sidewall.

Planing the core edge smooth.

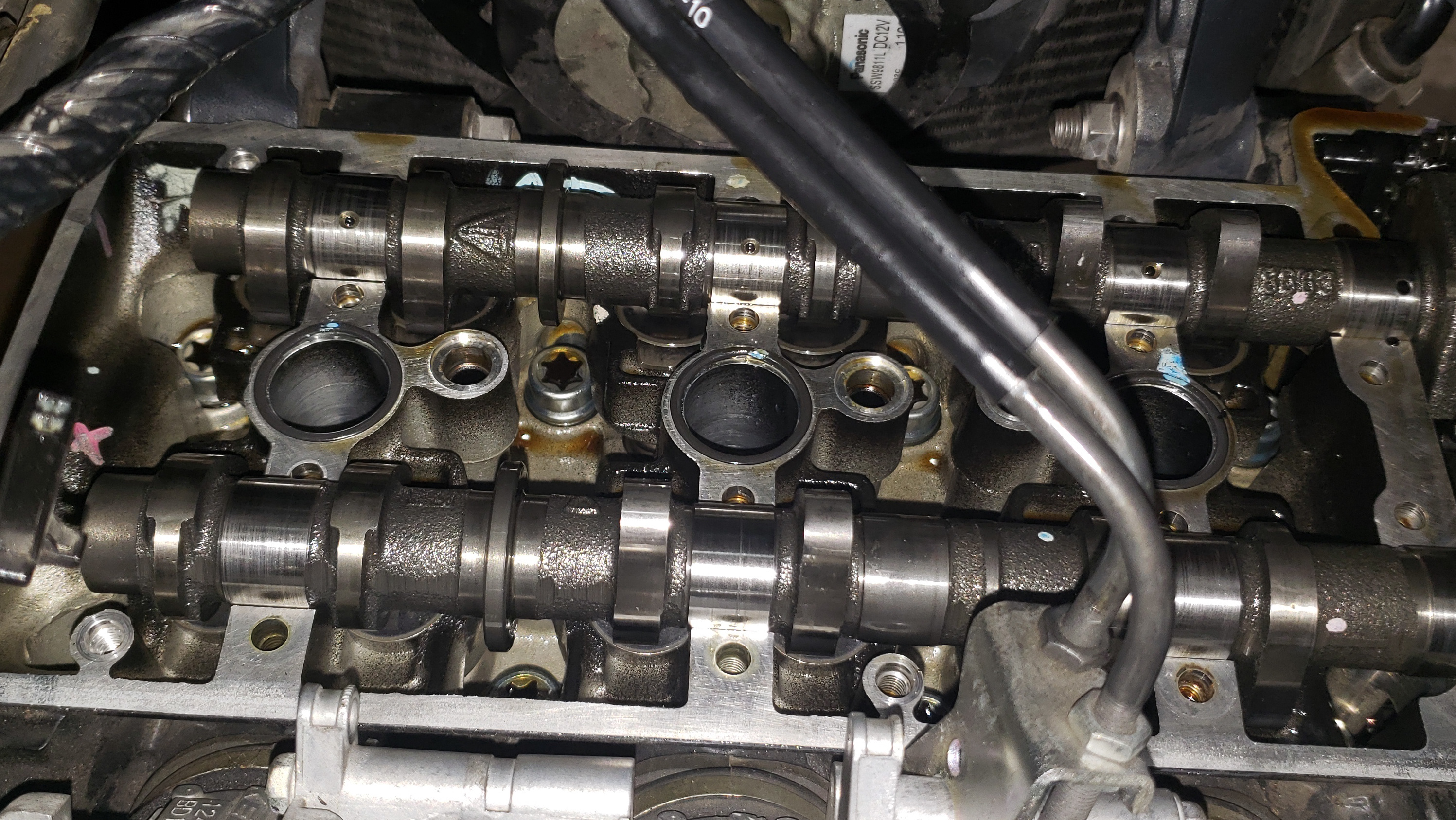

Before.

After.

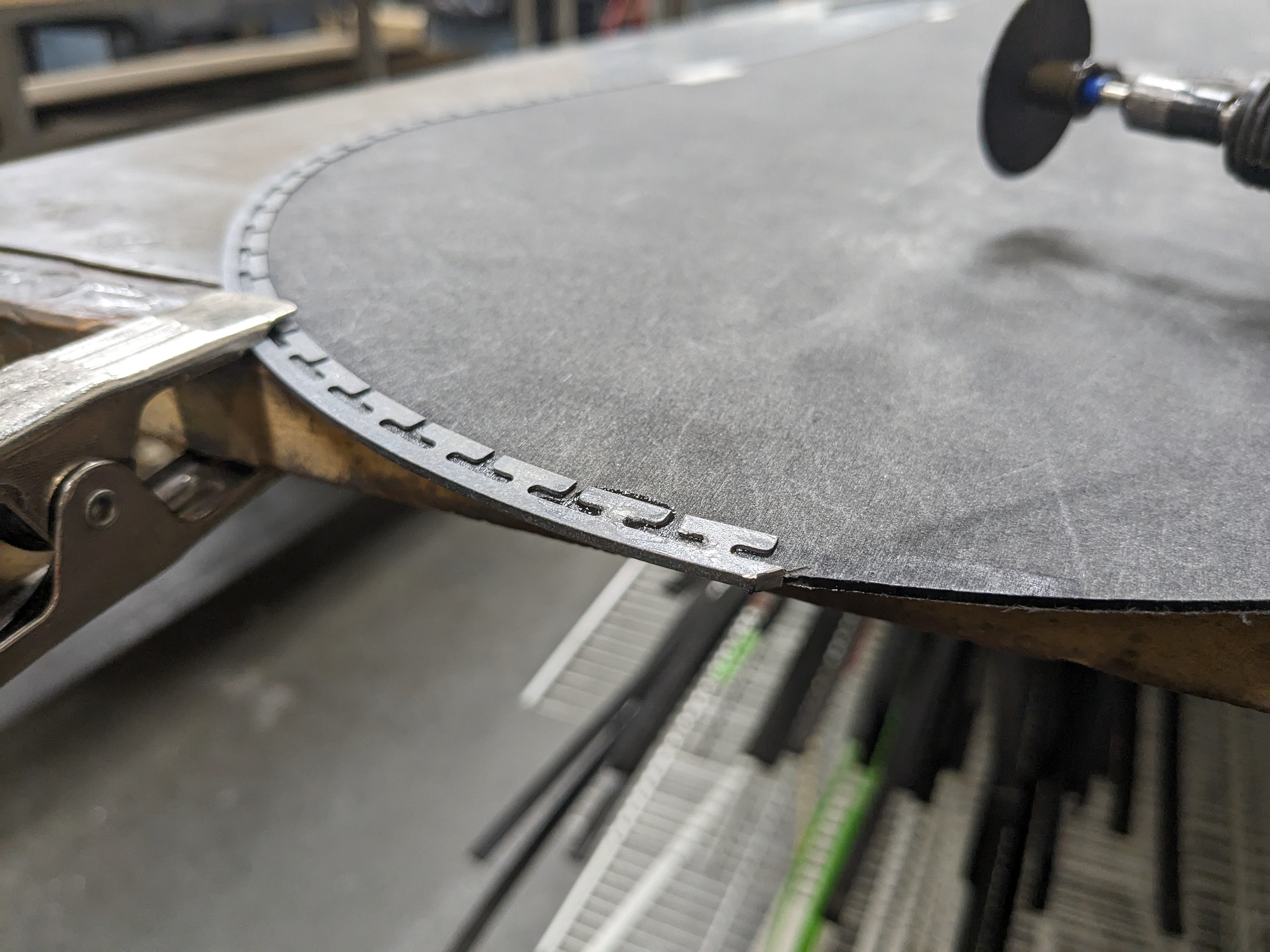

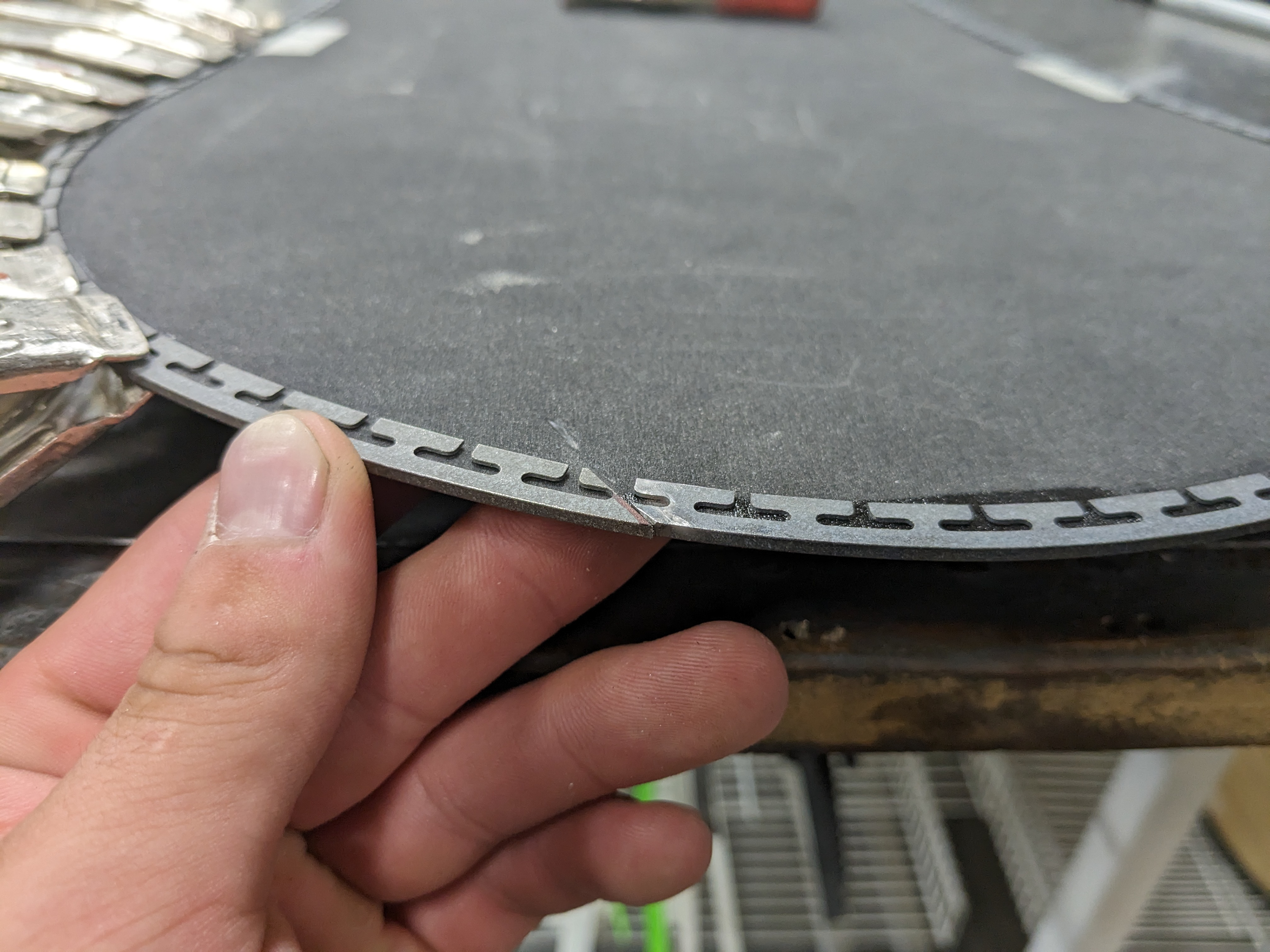

Test fitting sidecut.

Prepping to bend edge to fit.

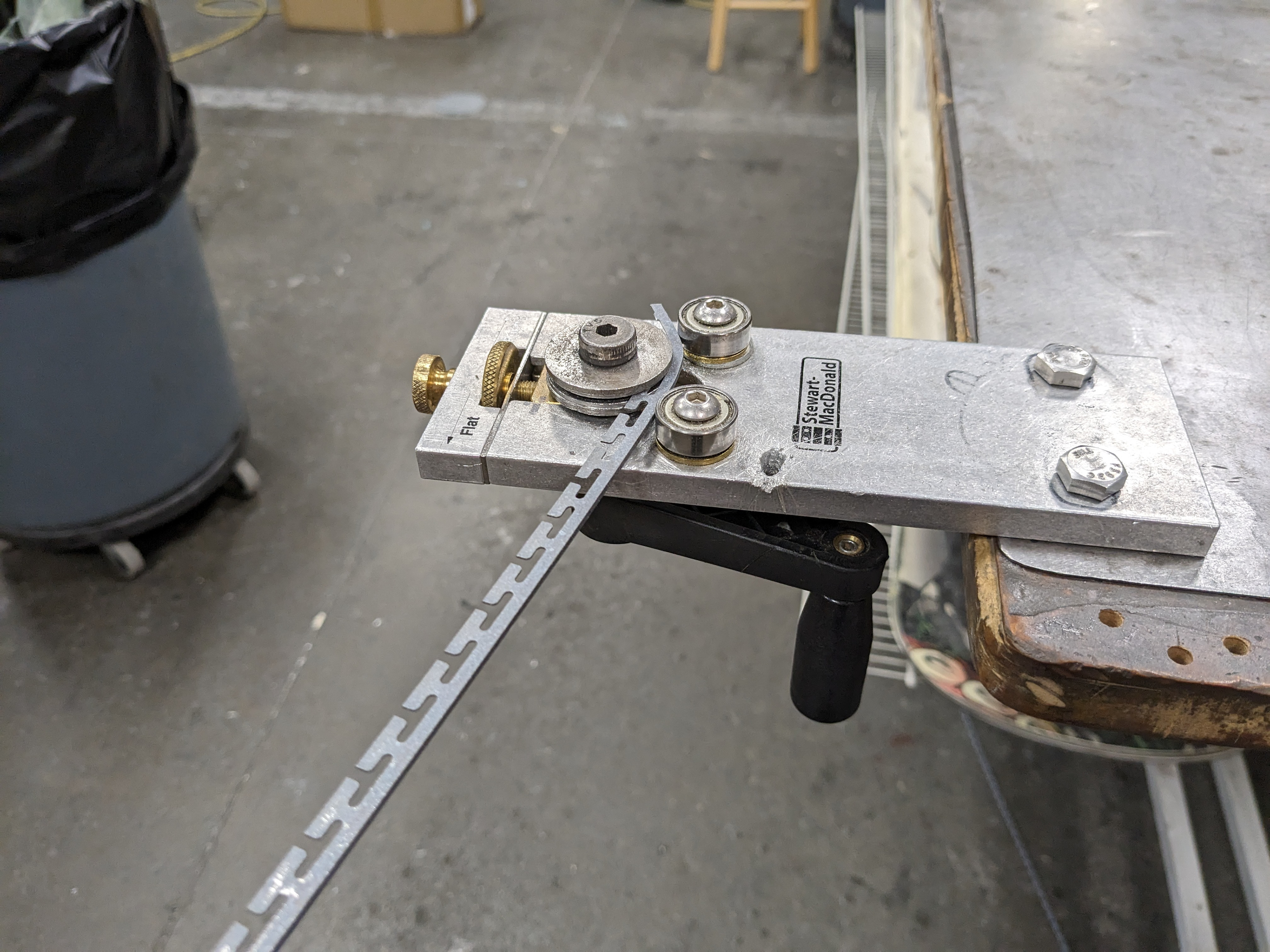

Getting pre-bend using a modified guitar building tool.

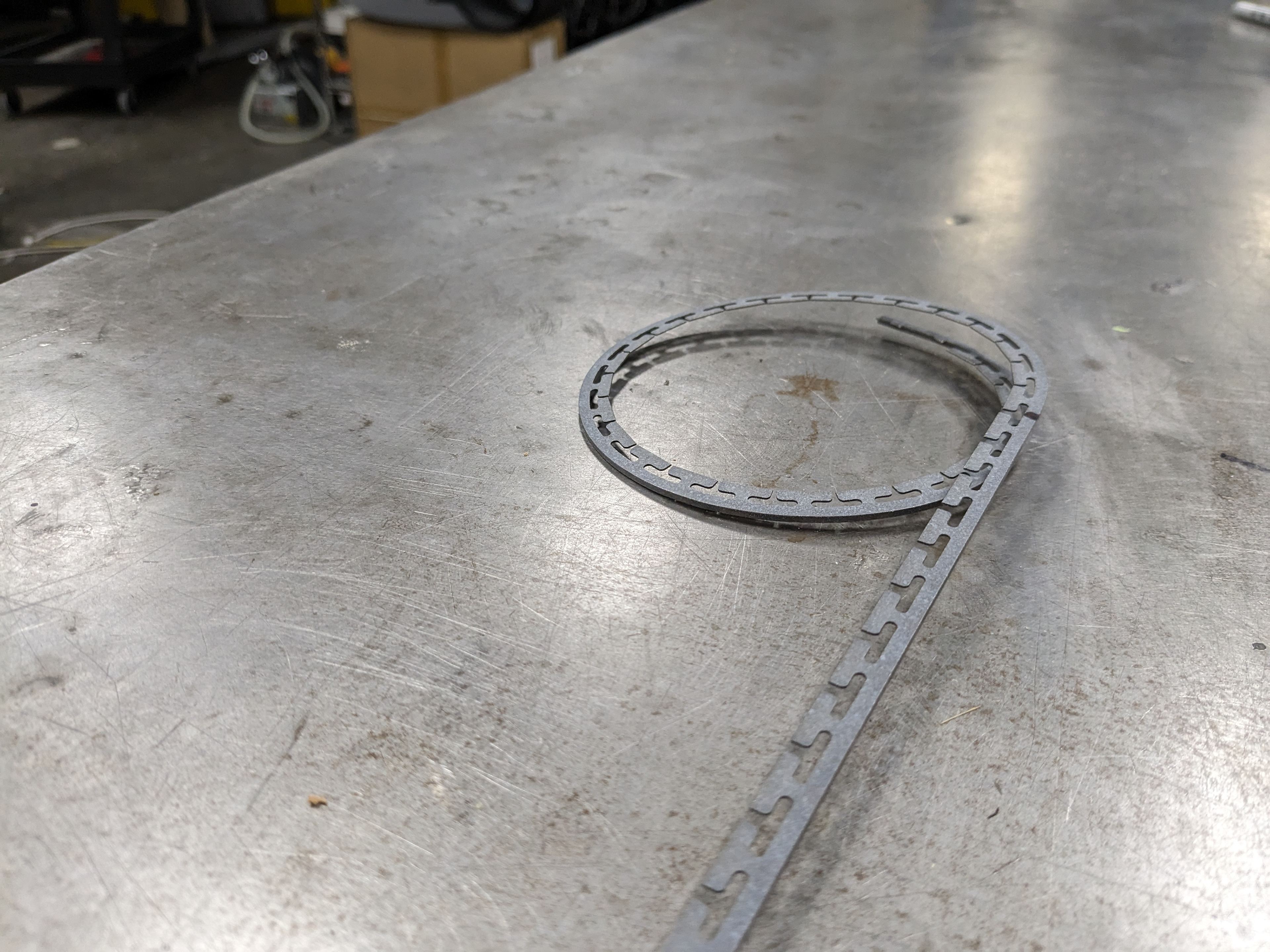

Pre-bend is a lot sharper than the bend.

One edge fitting pretty well.

Both edges fitting pretty well.

Gluing sidewall.

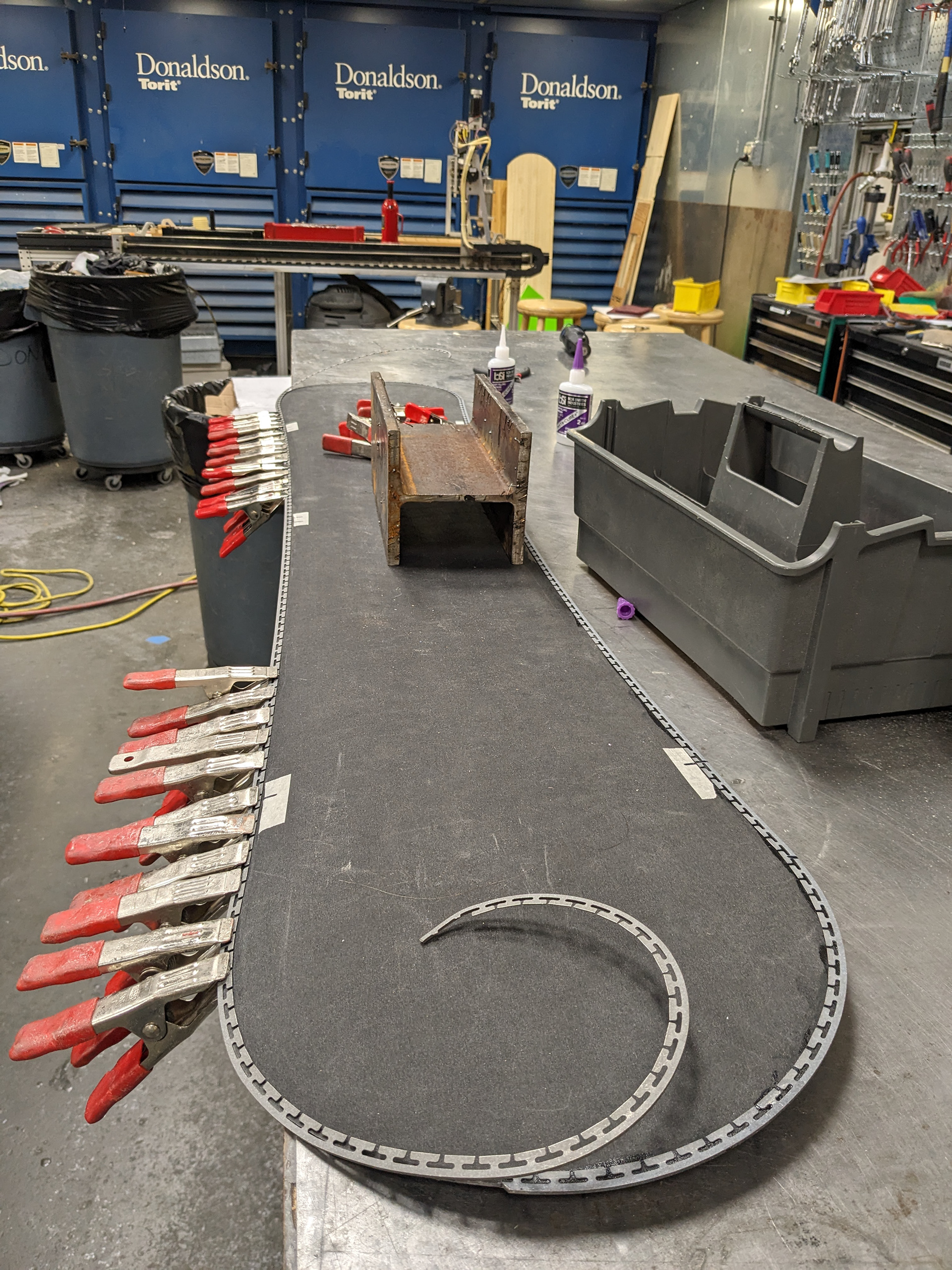

Gluing edges.

Gluing edges.

Other sidewall going on.

Trimming sidewall.

Both sidewalls on!

Now to fix those petty cracks!

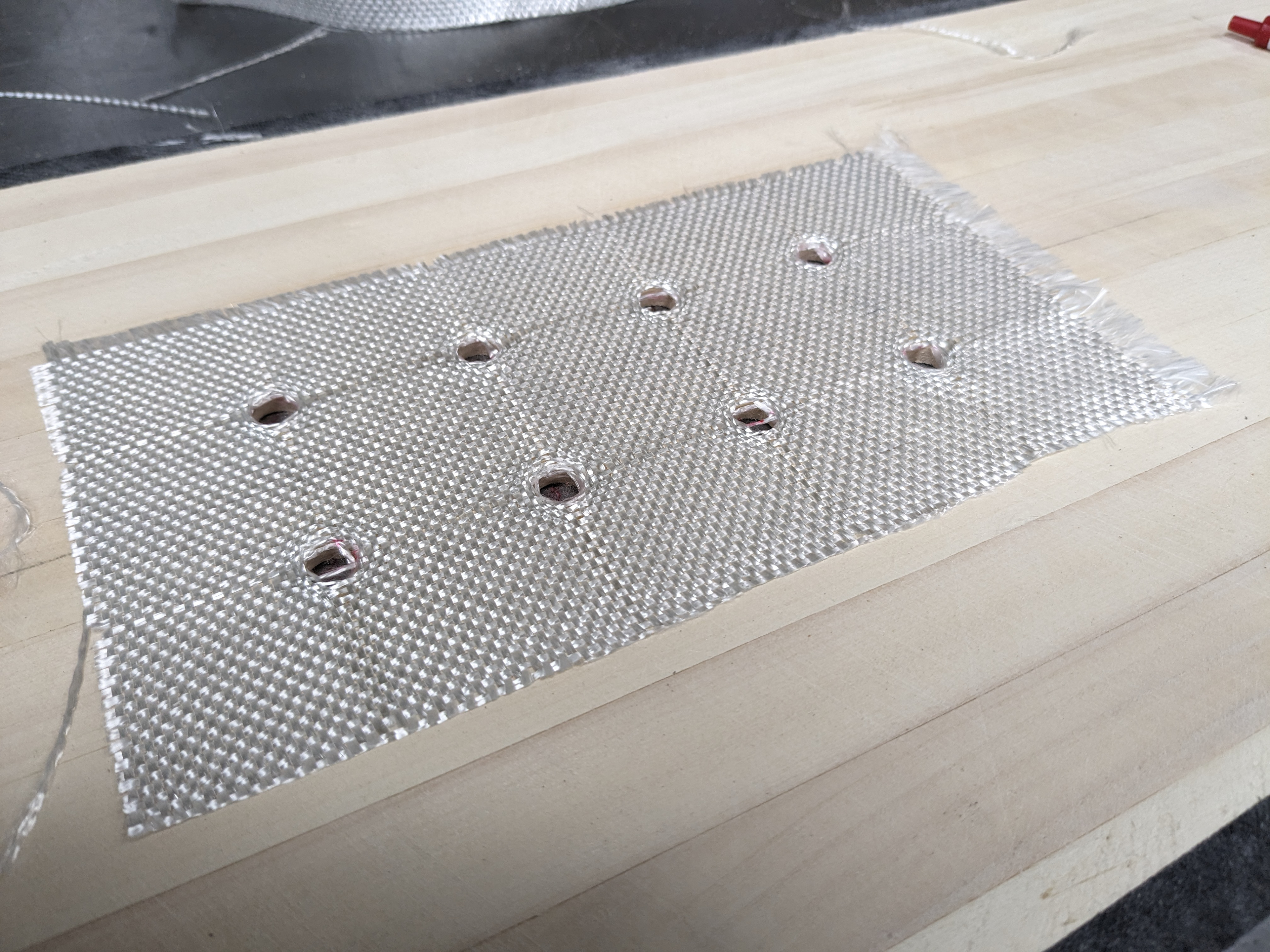

We just use fiberglass fabric to patch these spots. 3M 27 to quickset the fabric, then superglue to actually bond it.

Patch!

Patch

We also want to reinforce the sidewall interface before we plane the core+sidewalls.

Planing the core+sidewalls down!

We roughen the sidewall and core to help with bonding.

All of our graphics :)

Edges glued up, still need trimming.

Time to snip.

Snip snip.

Now grind down flush.

Perfect!

Edges looking great!

Roughening the sidewall.

Roughening the core, this will help prevent delamination. We do straight-lines to act as "tear-stops".

Tip fill!

Attaching the tip fill.

Attaching the tip fill.

Attaching the tip fill.

Snip snip the tip fill.

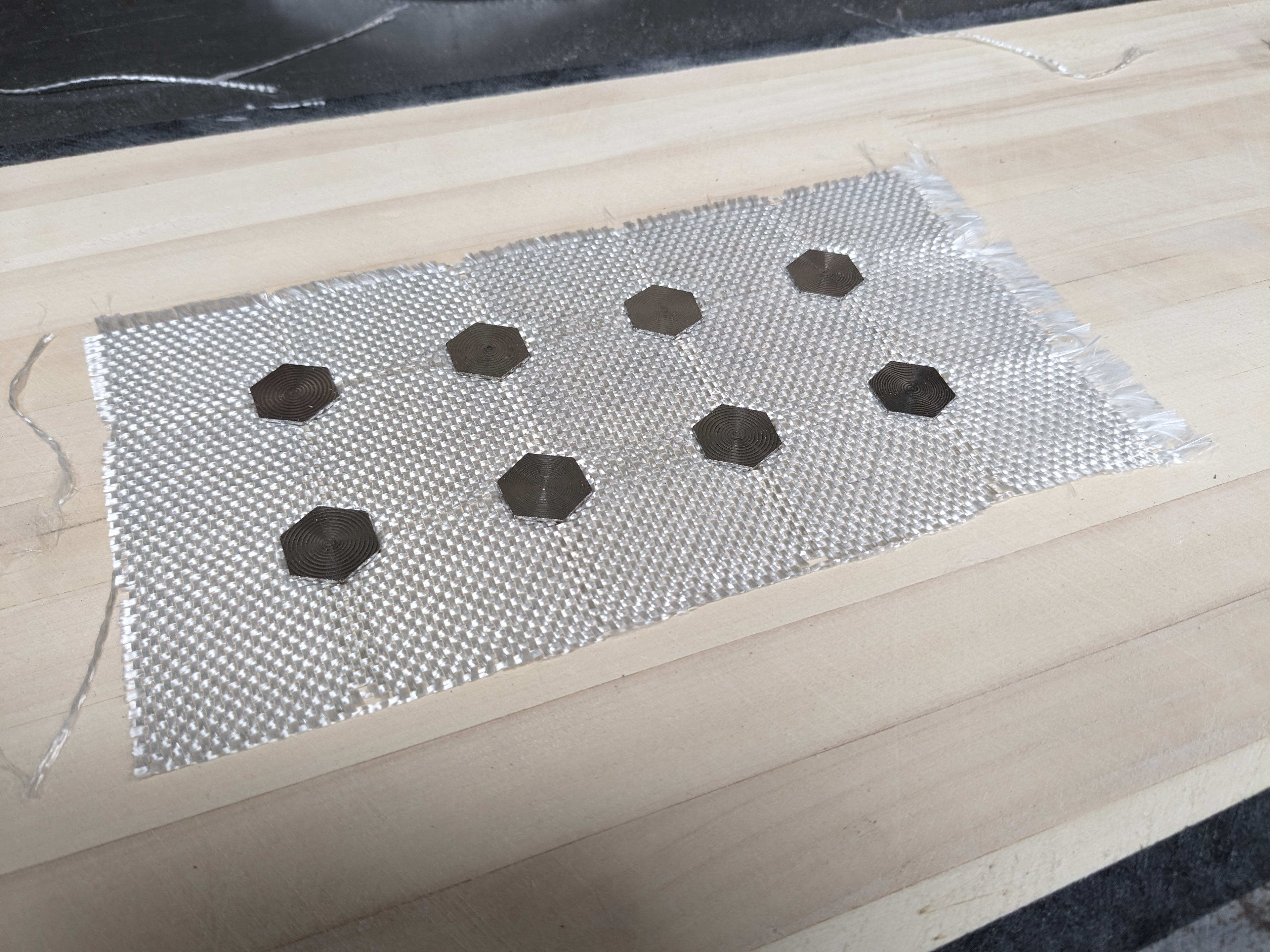

Fiberglass.

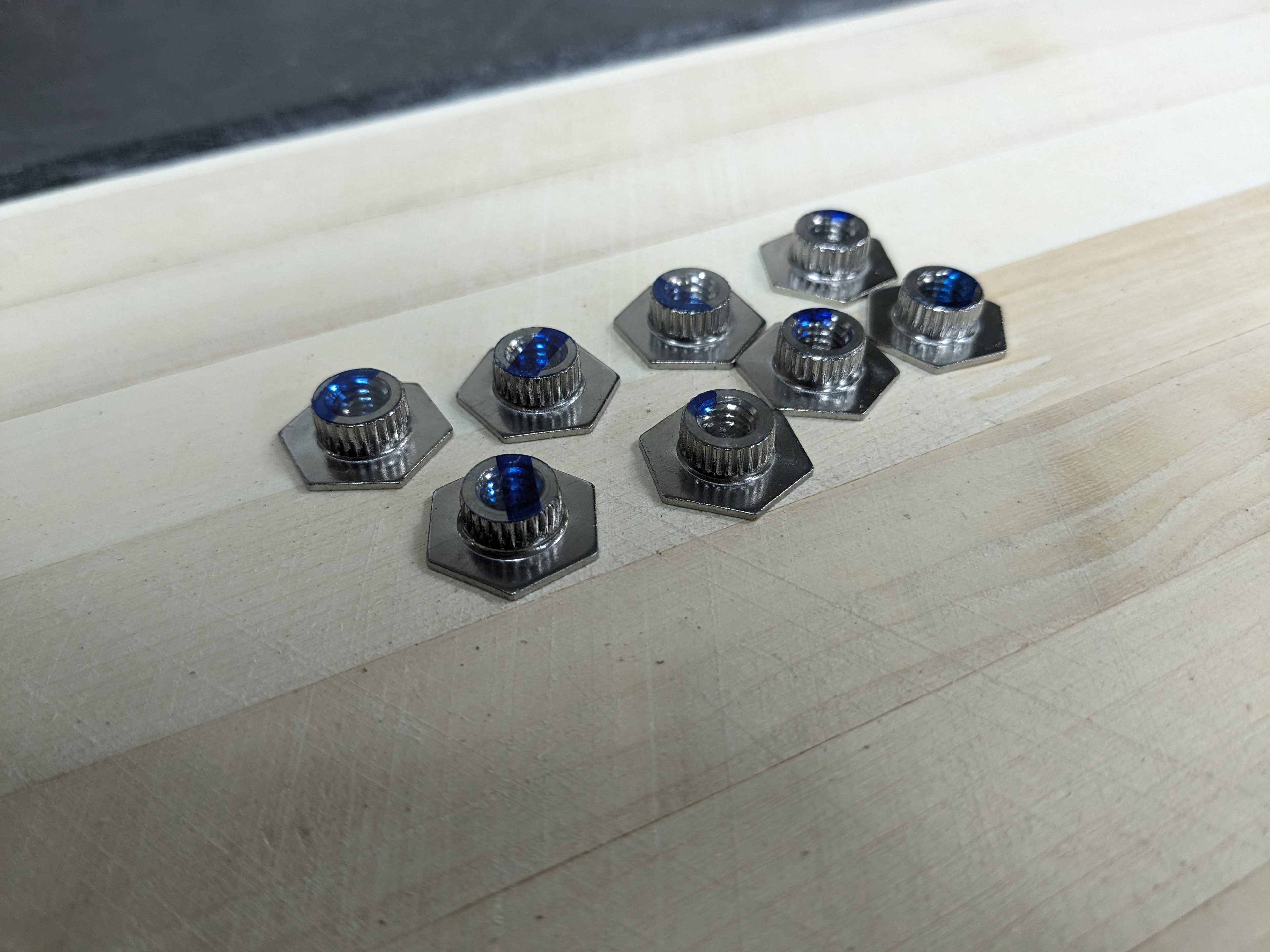

Threaded inserts.

The fiberglass prevents the inserts from pulling through.

Installed inserts.

Installed inserts.

Installed inserts.

Carbon fiber tows to make this board stiffer!

Plastic sheet to minimize the amount of epoxy getting on the base.

Ready for layup!

Base, fiberglass, carbon tows + core + sidewalls + tip fillers + edges, fiberglass, top sheet.

Vacuum bag, commercially they don't use vacuum bags. Vacuum bags are less time efficient, but should get you a lighter board with better squeeze out.

Vacuum gauge.

Putting the camber into the board, this must be done before the epoxy sets.

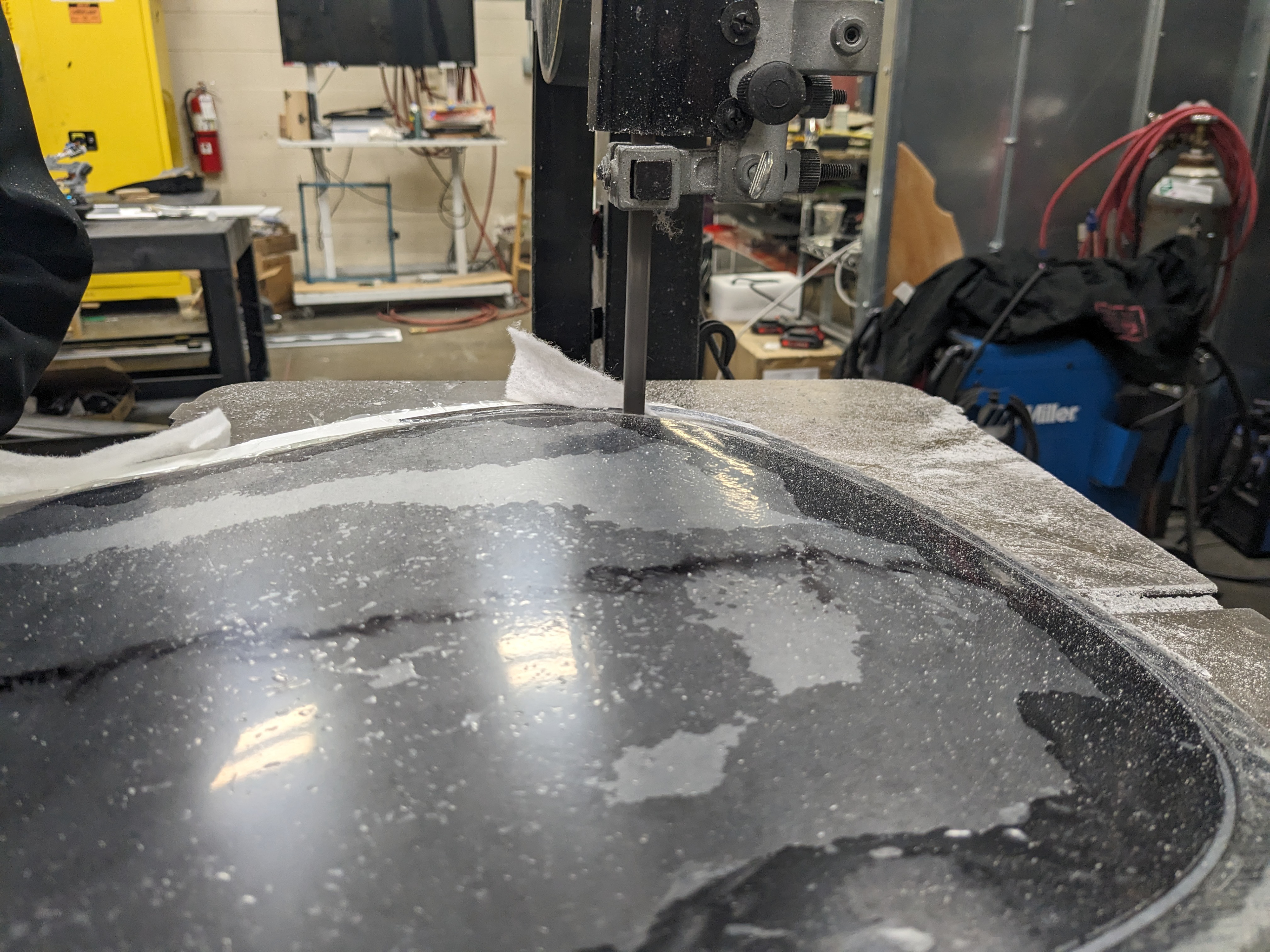

Cutting out the board.

Excitement builds!

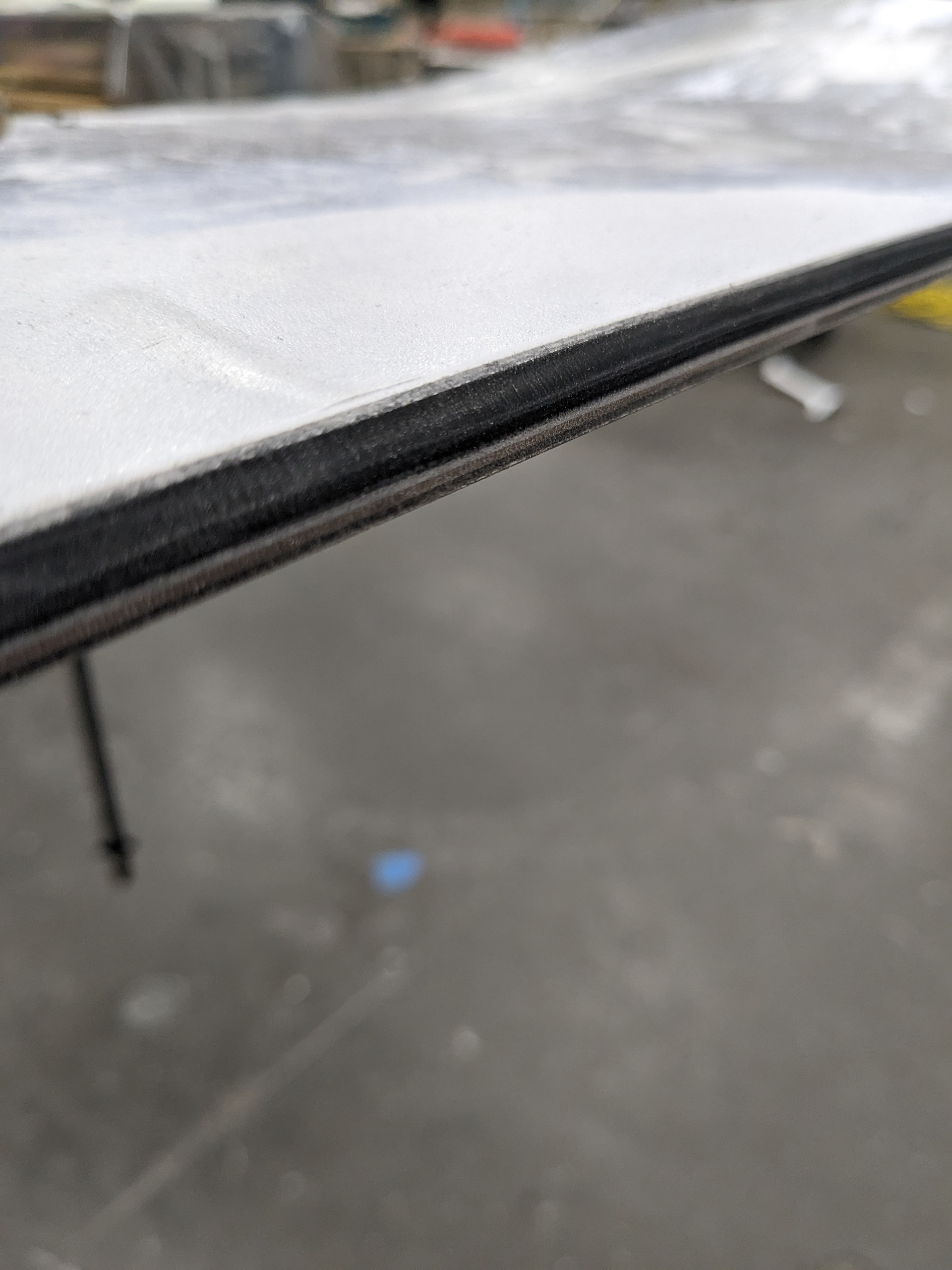

Time to add the sidewall taper.

Router to cut the taper. I did not do this part.

This leaves a nice taper, but a taper which will need smoothing!

The scary part, locating the inserts with magnets and drilling the top sheet out.

Some holes drilled.

Phew, all the holes drilled with no misses!

Phew, all the holes drilled with no misses!

Countersink those holes :)

Rounding the topsheet edges, this will prevent delaminations and looks nice.

Smoothing it.

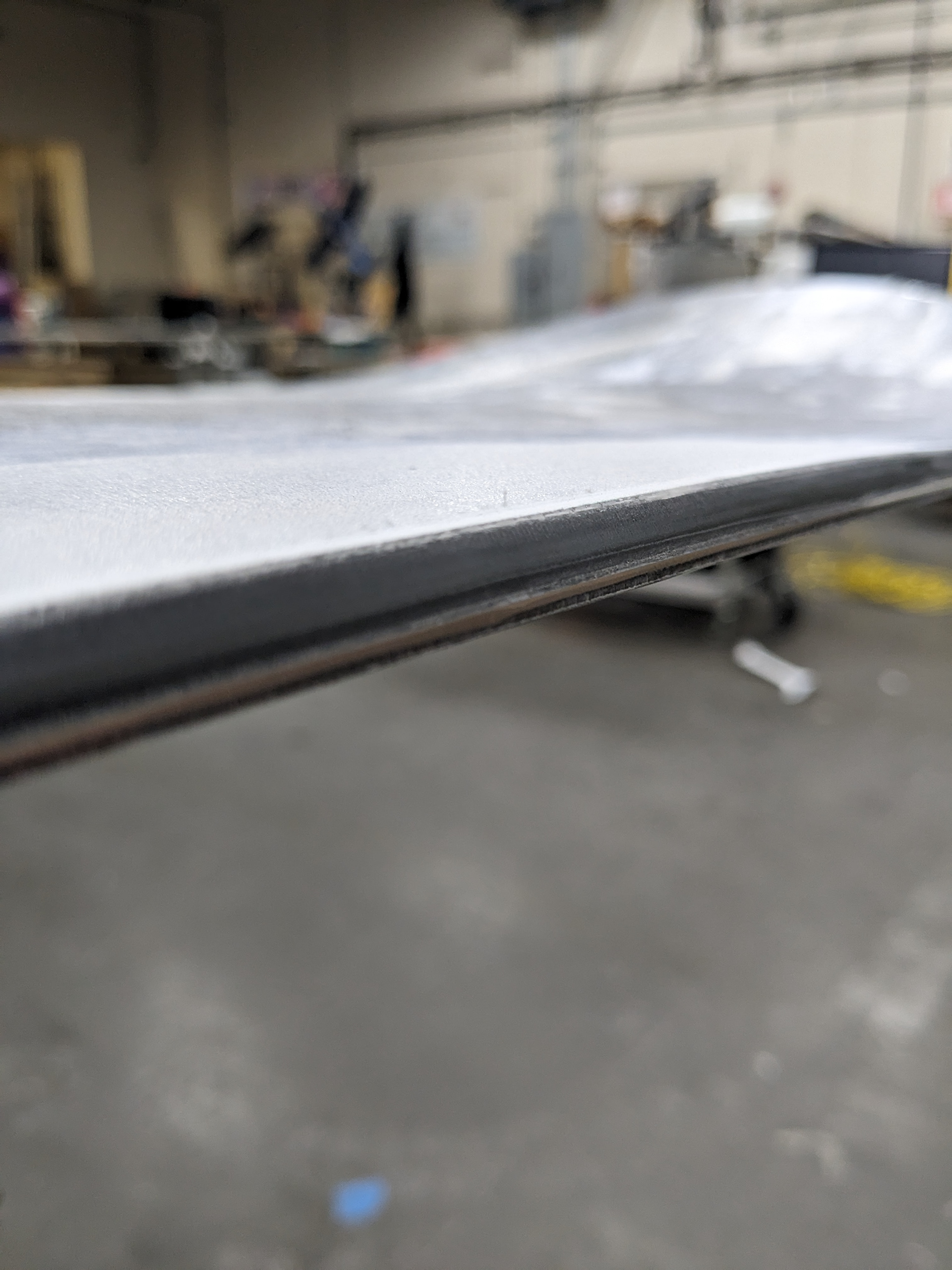

Before smoothing sidewall.

After smoothing sidewall.

Peeling the plastic off!

Isn't it purrrrdy?