A cool October's night in Minnesota at Elliott's.

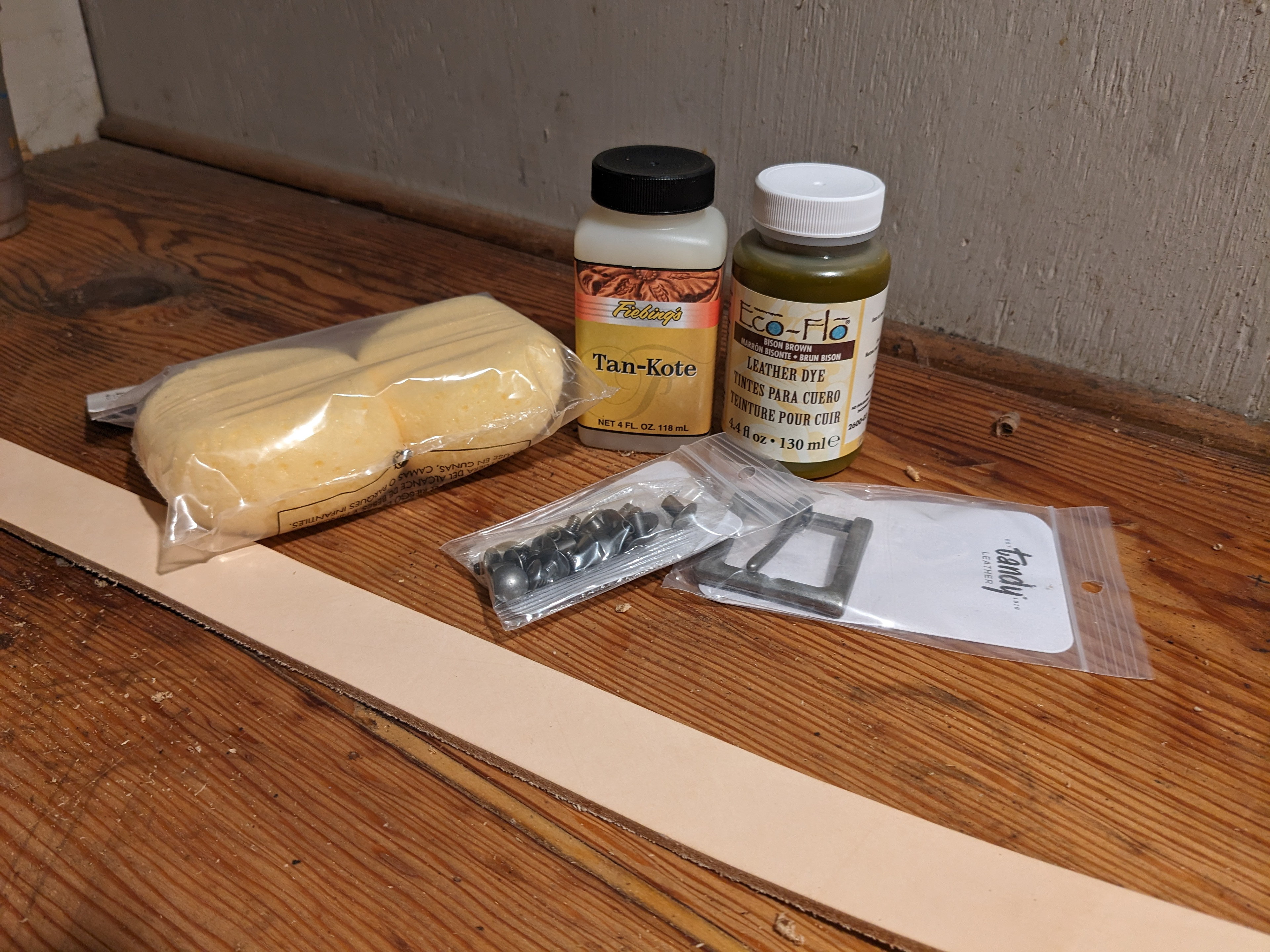

The raw materials.

Testing out the dye and comparing to a couple of store bought belts.

Cutting the belt to length.

Using some of the scrap to cut out the belt loop.

Dyeing the belt loop.

Burnishing the edge of the loop.

Punching holes.

Bending the loop.

Stitched up all pretty.

The area where the belt folds over itself needs to be thinned. A wood plane works alright!

Cutting the slot out where the buckle will go.

Thinning it some more.

Test fit.

Dampen and squeeeeeze to retain the bend.

Marking the end of the belt.

Cut out round.

Punching holes for hardware featuring Gabby!

Psssst, they may look like rivets but they're actually screws.

Punching holes for the buckle.

After this all that was left was dyeing the belt.

Complete!

Super happy with how it turned out :)